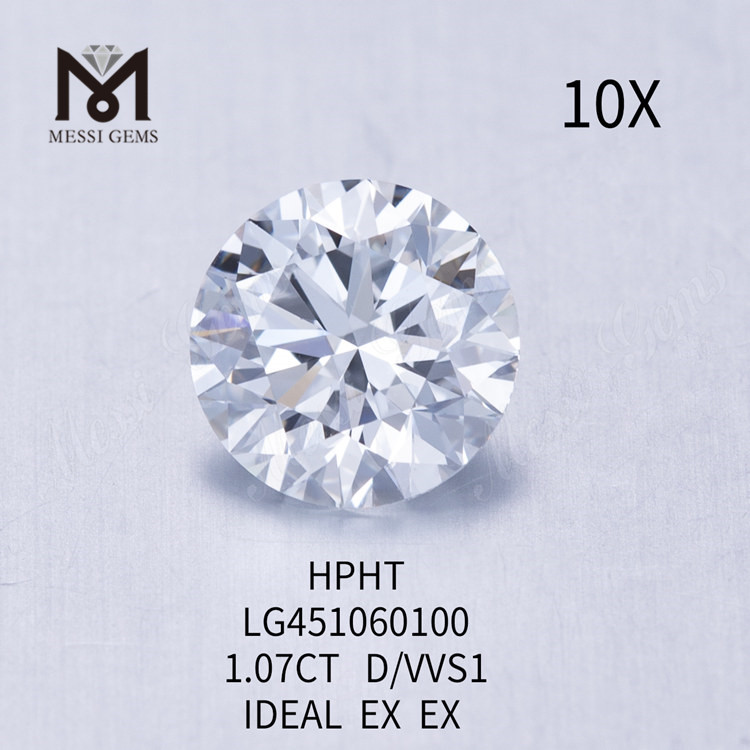

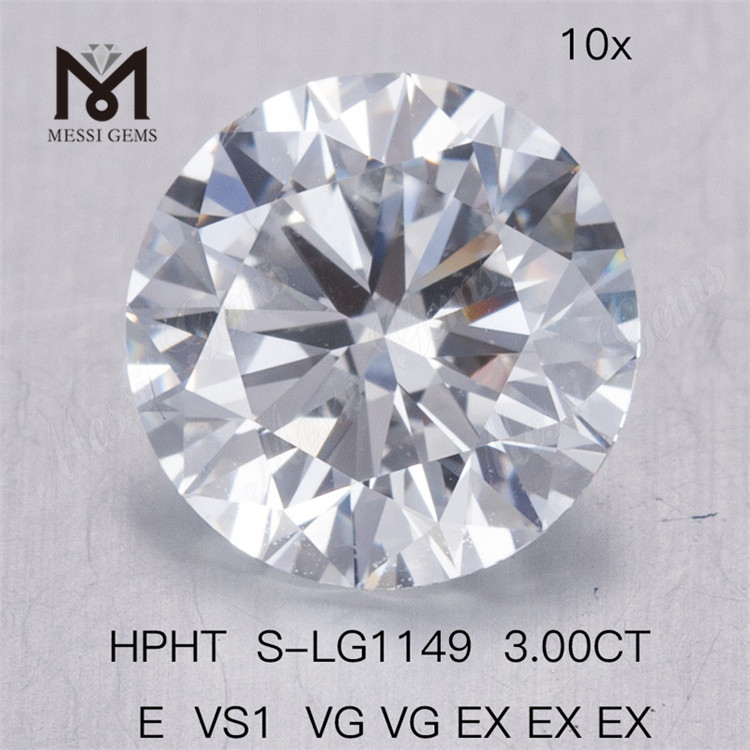

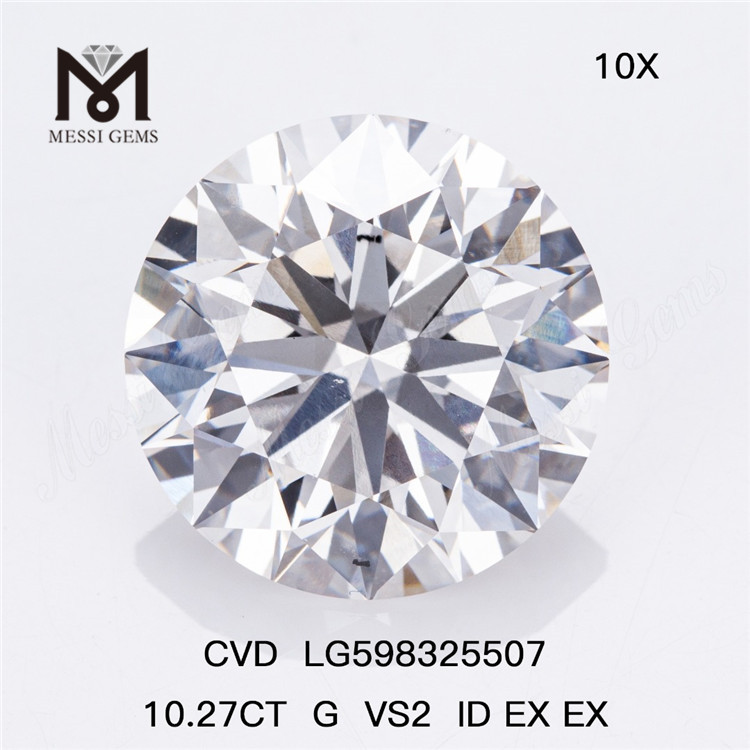

CVD diamond

Natural gas and hydrogen are heated to form a carbon plasma in a dishwasher-sized pressure chamber, which is deposited on the carbon substrate at the bottom of the chamber and gradually accumulates and hardens to form diamond flakes, which are then cut into gemstones. The shape is then cut into gemstones.

Compared to other types of synthetic diamonds, CVD diamonds can be produced in larger sizes and with greater precision. They can also be created with specific characteristics, like specific colors or the ability to conduct electricity, making them useful in a range of industrial applications, including cutting tools, electronics, and optics.

One of the key advantages of CVD diamonds is their purity. Because they are created in a controlled environment, they do not contain many of the impurities typically found in natural diamonds or other types of synthetic diamonds, such as boron or nitrogen. This makes CVD diamonds particularly well-suited for use in high-precision scientific instruments or as gemstones in jewelry.

Overall, CVD diamond technology has advanced significantly in recent years, leading to increased production efficiency, higher quality results, and a wider range of applications.